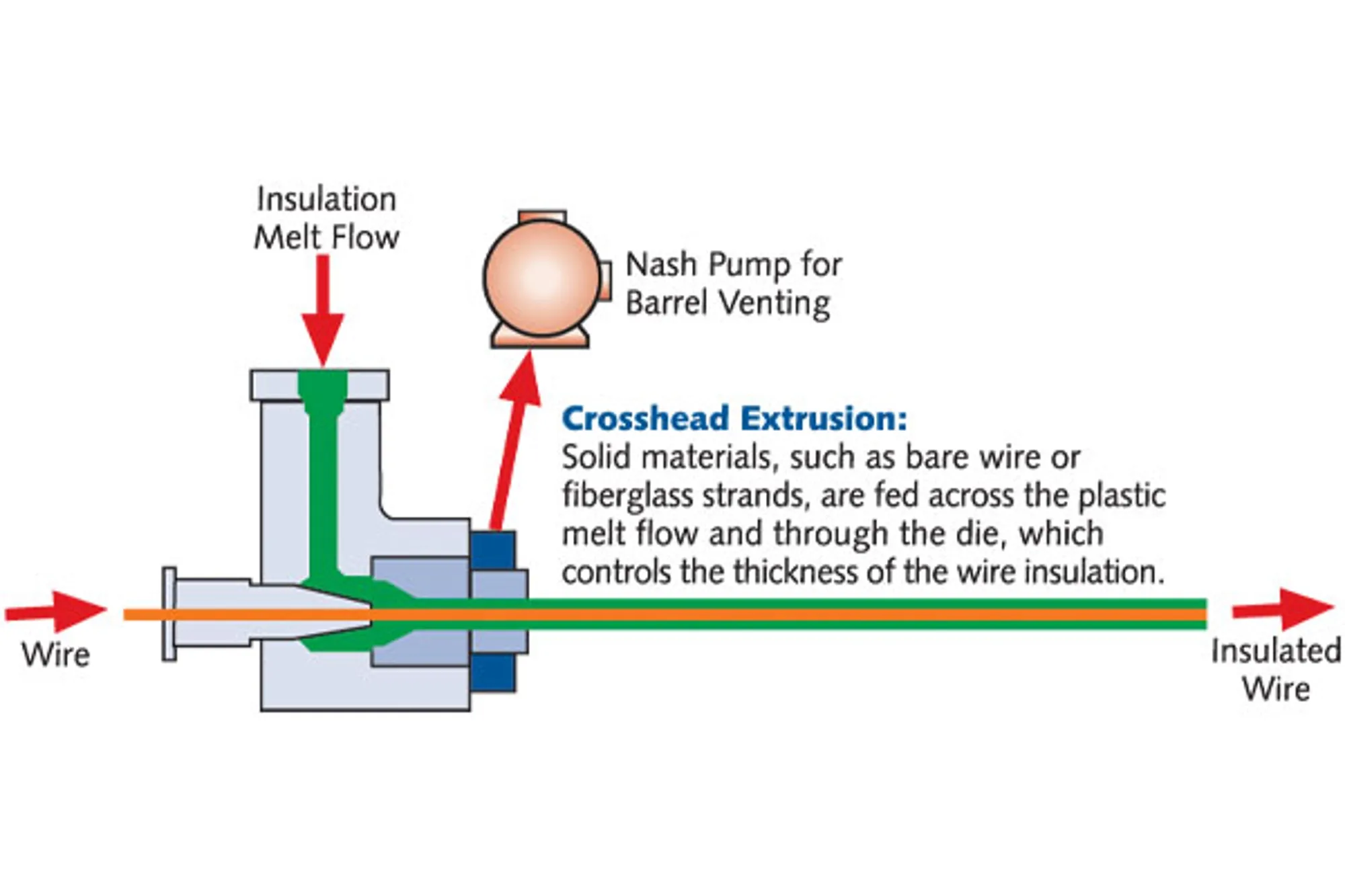

Plastic extrusion is a manufacturing process used to create long objects of a fixed cross-sectional profile. The material, like plastic, is drawn through a die of the target profile shapes and forms a continuous length of that shape. Vacuum is used during the process of plastic extrusion to create a variety of items like custom plastic profiles, extruded rods and tubes, piping, edges, molding, specialty plastic coatings, and multi-material extrusions known as co-extrusions.

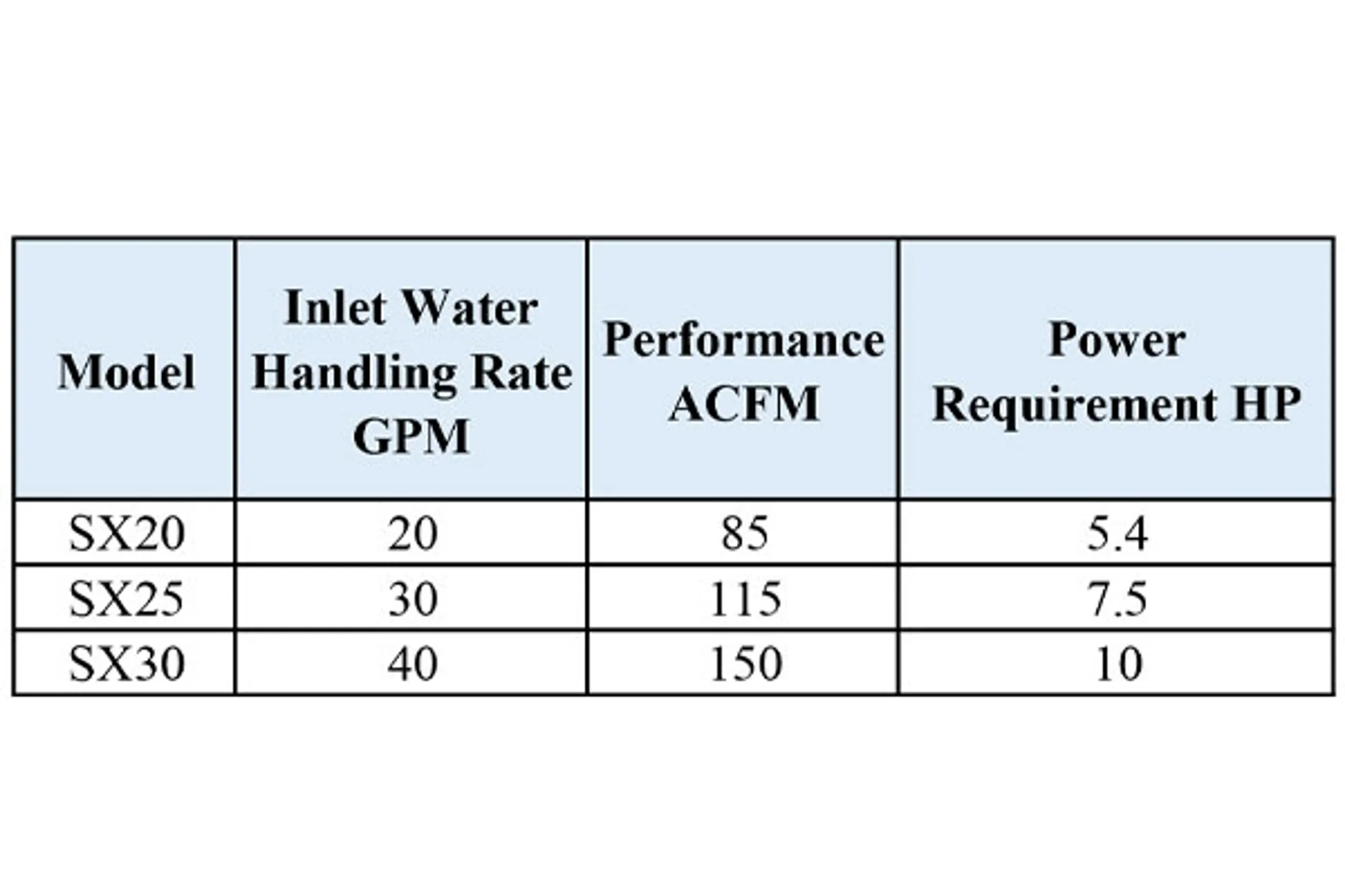

Nash recognizes the varying vacuum demand required by the plastic extrusion industry; therefore, our vacuum pumps can be configured to handle the water carryover associated with sizing and calibration tables as well as optimizing for extruder barrel venting.