Nash vacuum systems are essential components in combined cycle power plants, designed to optimize energy efficiency and enhance overall performance. These systems play a critical role in maintaining low condenser pressures, which is vital for improving the plant's thermal efficiency and overall power output. With decades of expertise and a strong focus on engineered-to-order solutions, Nash ensures that each vacuum system is tailored to meet the unique requirements of modern power plants, as demonstrated in projects like the world-record-setting Keadby 2 power station in Great Britain.

Reach Out to Our Experts

Have questions or need more information? Choose one of the options below to contact us, request a service, or request a quote

Key Benefits

- Improved Operational Efficiency: By reducing total system pressure through effective air extraction, Nash vacuum systems help power plants achieve higher thermal efficiencies.

- Cost Savings: Enhanced energy efficiency results in higher electrical output and reduced need for additional fuel sources, lowering operational costs.

- Longevity and Reliability: The robust design and high-quality materials ensure that Nash vacuum systems provide dependable performance, even in extreme conditions like high temperatures or earthquake-prone areas.

- Sustainability and Environmental Responsibility: Effective flare gas recovery and optimized condenser pressures contribute to lower CO2 emissions, showcasing a commitment to environmentally friendly operations.

Nash is proud to support power plants with customized, high-performance vacuum systems that contribute to setting industry benchmarks, such as the Keadby 2 power station's world record for efficiency at 64.18%.

Key Features

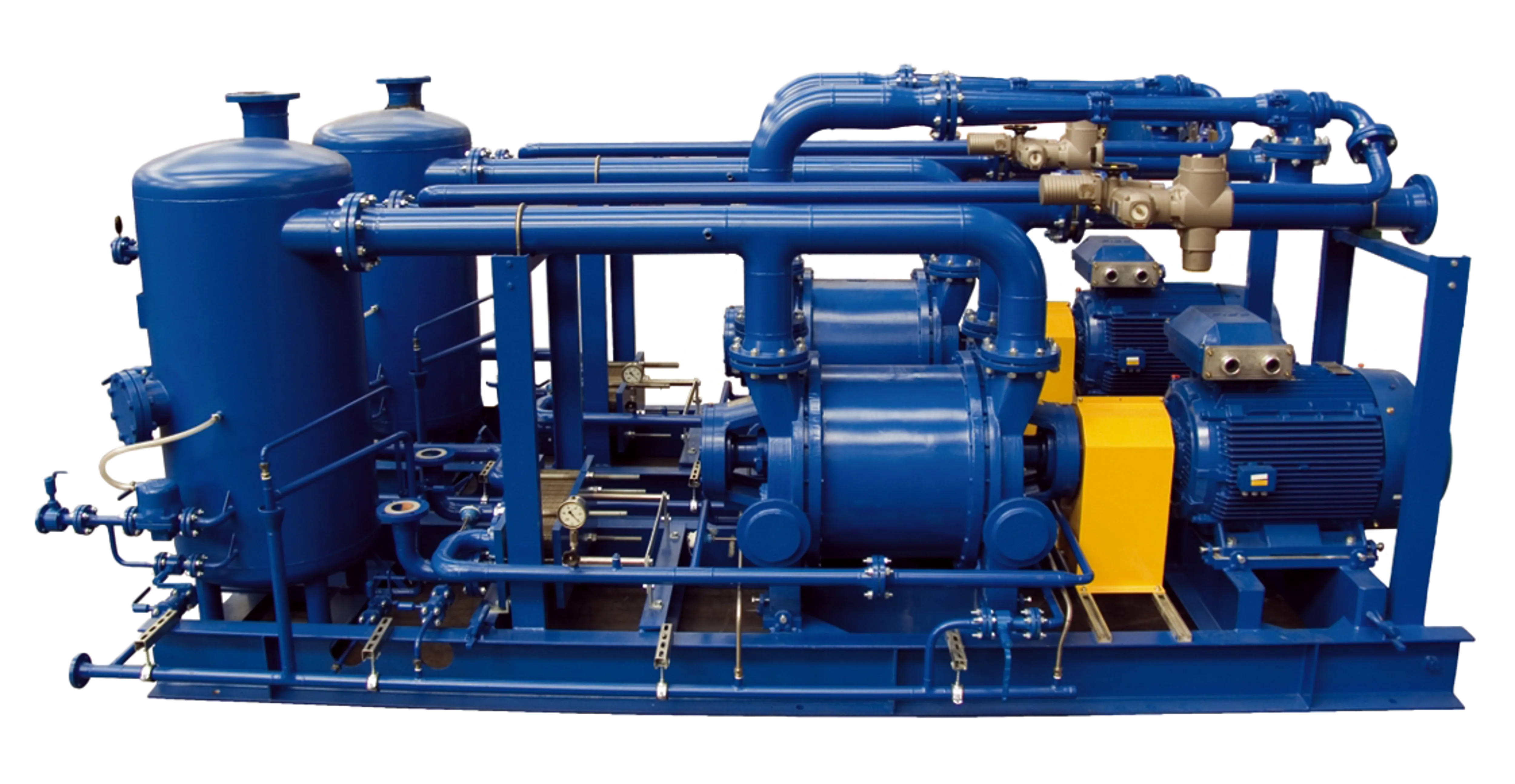

- High Capacity and Performance: The Nash vacuum systems are built to handle high volumes and maintain optimal performance even under demanding conditions. For instance, the Nash 2BW4 system, used in the Keadby 2 project, exemplifies our dedication to power and reliability.

- Optimized Footprint: Compact design to reduce installation space without compromising performance.

- Advanced Safety Features: Cavitation-proof design to perform under varying operating conditions and condenser pressures.

- Custom Engineered Solutions: Each vacuum system is engineered to order, ensuring it meets specific local and operational requirements.

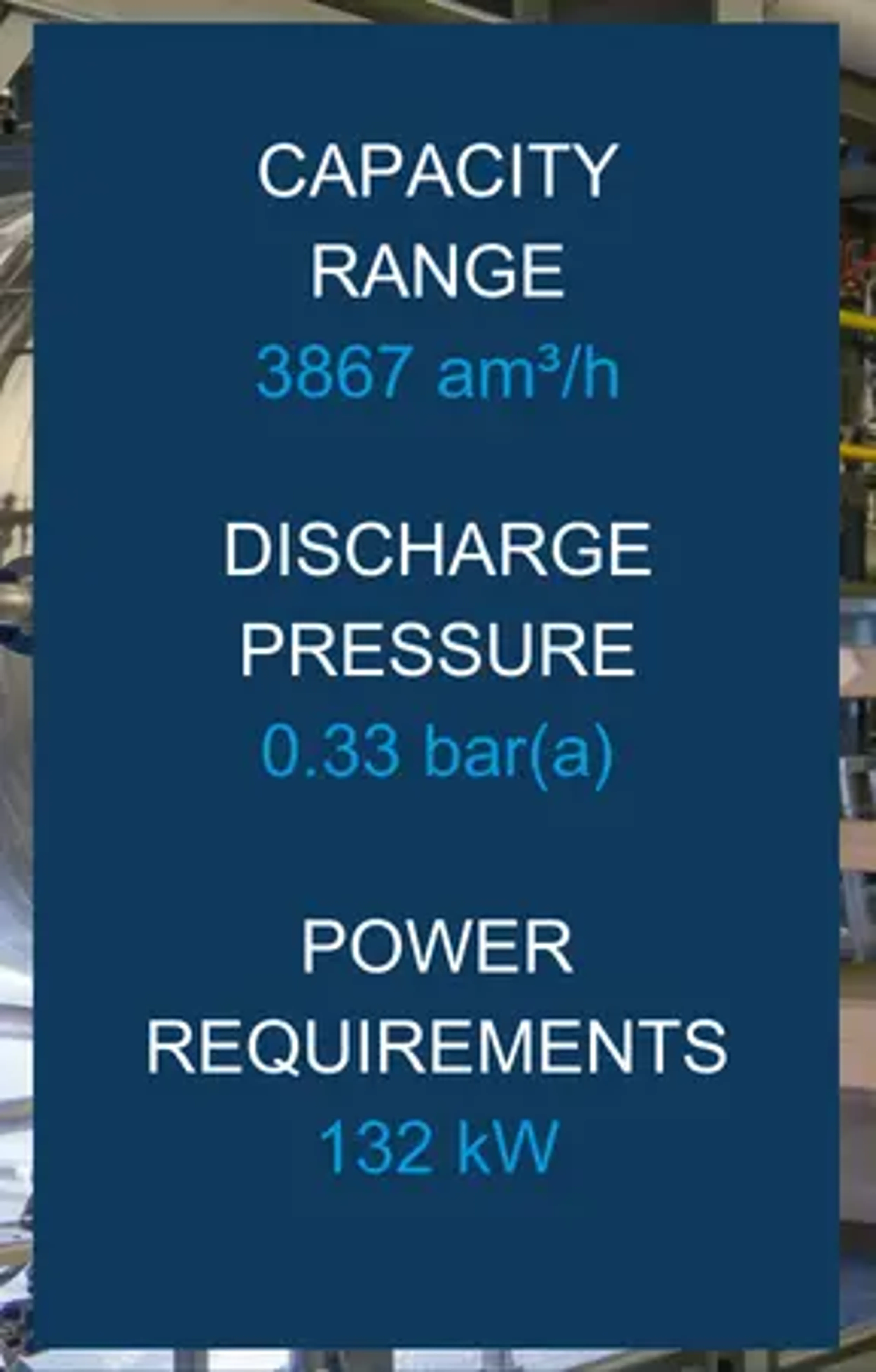

Technical Specifications

Components of a Typical Package:

- Primary pump units (e.g., Nash 2BE1 series)

- Separator and air- or water-cooled heat exchangers for uninterrupted operation

- Control panels and instrumentation for seamless operation

Performance Metrics

- Capacity: Can handle up to 3867 am³/h per unit, achieving a total system capacity of up to 23 MMSCFD in multi-unit setups.

- Discharge Suction Pressure: Depending on local design parameters, capable of reaching a maximum suction pressure of 0.33 bar(a) and below.

- Power Requirements: Each pump demands only 132 kW at the design point.

Materials of Construction: SS316L for optimal durability and chemical resistance.

Compliance with Industry Standards:

- Certified to meet ASME, API, NEC, and European directives (Machinery, Pressure Equipment, Low Voltage Directives).

- Available configurations also meet UKCA, ASME, NEMA, HEI, and other local standards.

Applications

Common Use Cases:

- Air extraction in condensers to maintain low pressure and maximize power output

- Effective gas recovery and extraction in power plants for improved sustainability

Industries:

- Power generation (combined cycle and thermal power plants)

- Energy facilities prioritizing environmental compliance and efficiency

Specific Scenarios:

- Performance during seasonal temperature shifts, where cooling water temperatures impact condenser pressure

- Situations requiring high reliability to prevent cavitation and ensure continuous operation

Read Our Case Study

Learn from the success of Keadby 2 Power Station and understand the economic and environmental benefits of using Nash Vacuum Systems.